How It Works: The Basics of Clean Room HVAC Design

This is a vital part of clean room HVAC design. Heating, venting and air conditioning (HVAC) are essential for dust-free air quality in a room. The temperature, humidity, and airflow need to be clearly defined in a clean room design when working with delicate processes so as the products that are being made are of high quality. Anlaitech Clean room HVAC design is a method for producing an atmosphere that satisfies specific levels of cleanliness to prevent contamination.

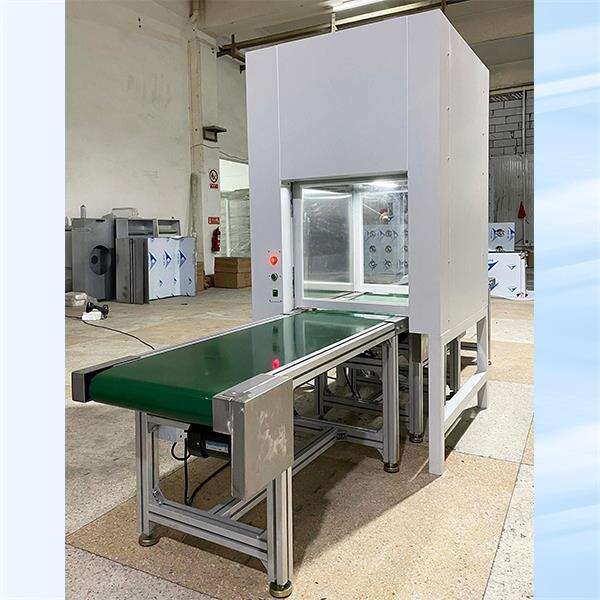

There are but numerous factors to be taken into account when designing a clean room HVAC system to maximize the efficiency. The first thing to factor is that a clean room needs to be designed in function of dimensions and configurations, so an estimate can be made at the cooling/heating capacity. It is also very important to ventilate properly so that clean air can circulate in the room. The type of filtration system can also make a big difference, as this image shows the benefits and drawbacks of each: (source) The first step is to take into account the modular clean room itself and what it needs in terms of cleanliness, the contaminants that are present, etc.

Optimal air quality in the clean room setting can be attained through proper clean room HVAC design. HVAC facilitates in controlling temperature, humidity, and airflow in the room, avoiding the accumulation of contaminants that may interfere with the room’s cleanliness. In addition to this, the HVAC ensures that the only appropriate air circulates within the premises by removing all air pollutants. In line with that, the air cleanliness and suitability standards are accredited through appropriate HVAC design that ensures that the HVAC achieves the intent air level in the clean room.

Filtration and overall airflow in the Anlaitech clean room HVAC design aid in achieving high standards of air quality. Filters the filter-contributed particles hence prevent there contamination of the air circulate. For proper filtration, High-Efficiency Particulate, Air filters are used in clean room HVAC systems. The HVAC filtration system is enhanced by proper clean room airflow, which ensures proper air circulation throughout the room. This way, filtration and airflow enhance optimal air quality in the clean room.

Common Mistakes to AVOID while Designing Clean Room HVAC System However, one of the more common mistakes involves forgetting about the unique cleanliness needs of a clean room and an HVAC system that does not meet those standards. It also commits the mistake of using poor quality filter systems, unable to remove fine particles from the air. Not only does poor airflow design make the room unnecessarily cluttered, but it can also cause poor air distribution and lower clean air room in some places. Proper HVAC design, while avoiding these mistakes will ensure the clean room is maintaining the required level of cleanliness and air quality.

To summarize, clean room HVAC design is one of the crucial factors that should be taken into consideration while constructing a space with no contamination or impurity. A particle counter clean room, considering three main features, attaining good air quality through filtration and airflow management, and avoiding mistakes are all required in order to keep a clean room appropriate for extremely sensitive processes. Anlaitech is one of the leading technology providers for clean room HVAC design solution to deliver the most reliable air quality for your clean room requirements.