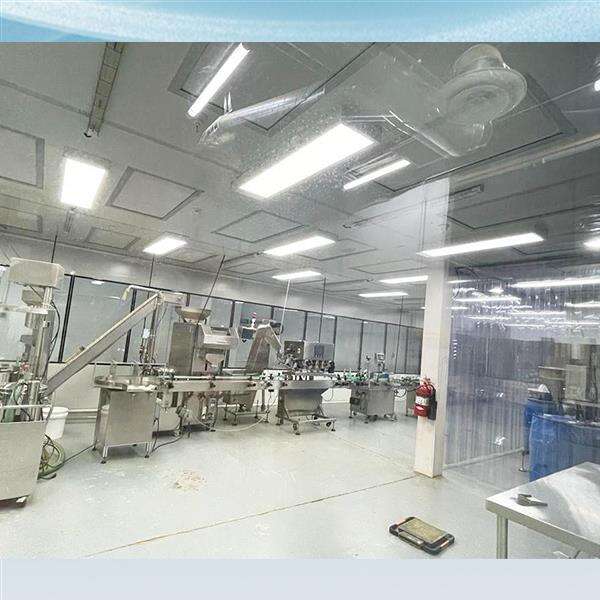

Ever wondered what it's like to step into a ISO 7 Class 10000 clean room? Let’s take a closer look at this extraordinary ecosystem, and learn how it works.

An ISO 7 Class 10000 clean room is a controlled environment in which Clean Room Project are kept to a minimum. This makes certain that the products being produced within the clean room aren't contaminated by outside substances. The atmosphere inside ISO 7 Class 10000 clean room is specially filtered equipment to removes dust particles and bacteria and so on.

Special training and aseptic equipment is needed for working in a clean room with a Optical Cleanroom cleanliness level. Workers are required to wear protective gear including suits, gloves and masks to minimize the risk of contamination. They also have to adhere to stringent protocols to reduce introduction of particles into the clean room.

They are ISO 7 Class 10000 clean rooms, as defined by the number of particles in the air. The smaller the number of the classification, the cleaner the room. Electrical Cleanroom are intended to meet defined cleanliness levels as set by the International Organization for Standardization.

ISO 7 Class 10000 clean rooms are required to adhere to certain level of standards for their efficiency. Those Medical Cleanroom are everything from monitoring air quality to keeping equipment up to date to following consistent sanitary measures. Using these guidelines, manufacturers can help to produce their products in a clean and confined space.

There are a number of advantages to using an Pharmaceutical Cleanroom in the manufacturing process. One of the key advantages offered is the capability to manufacture high-quality products that meet stringent quality guidelines. By ruling out the product environment the can guarantee the products will not be contaminated or defective.