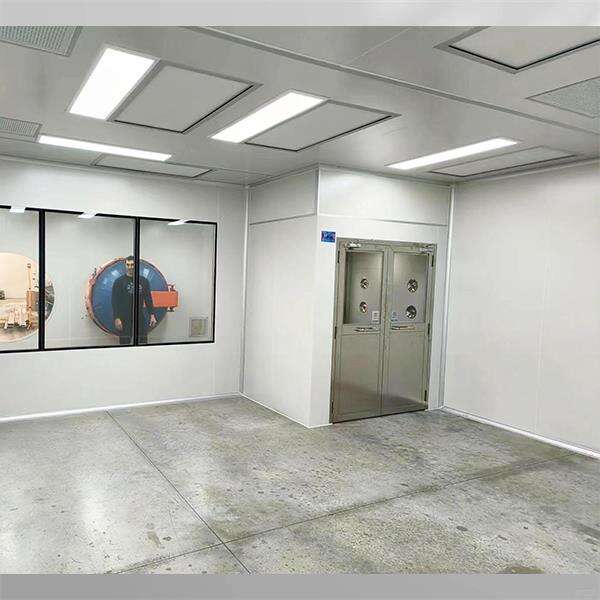

This importance of cleanliness goes up to an extremely high level in many places, such as hospitals and laboratories where the need for proper cleanliness is not only needed for experiments but also to ensure that patients do not get infected. One of the most crucial things for proper hygiene is a room that meets specific conditions. A room with ISO 8 Class is a category of space that has to meet certain cleaning standards in order for safety and cleanliness during the work

Industries like pharmaceuticals, electronics and food processing require an ISO 8 Class clean room, as tiny particles can contaminate products and lead to costly errors. Keeping the clean room as ISO iso class 5 cleanroom 8 Class helps you in getting safe, contaminant free and high quality products without any issue. This goes a long way in not only keeping workers from being exposed to potentially harmful substances that may be present in an unclean environment but also for them to feel pride and satisfaction in their work area which can promote higher levels of productivity.

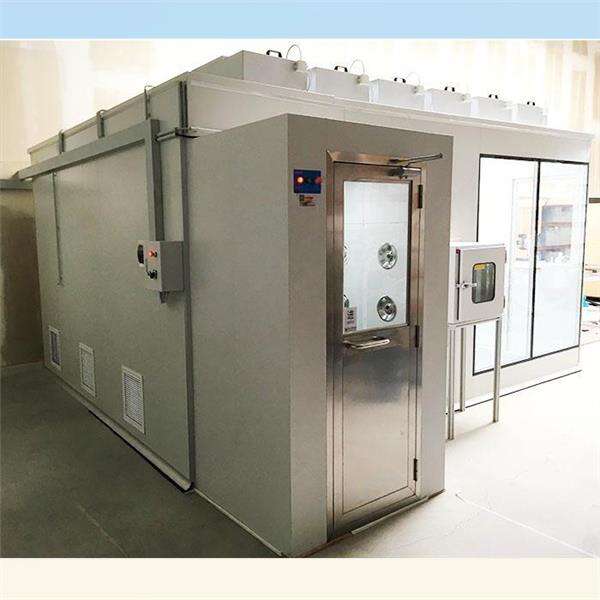

If you want to be up to the standard of ISO 8, your clean room would need routine cleaning and evaluation to ensure that your area meets the level of cleanliness that is required. This means using proper cleaning practices (ie, disinfecting surfaces and changing out air filters often). It also includes ensuring the room is perfectly clean by wearing hepa filter plenum box special attire like gowns and hairnets to avoid contamination from external sources.

There are a lot of advantages that come with operating in an ISO 8 Class clean room. It keeps your product in the best possible for for sales so that it remains a high quality, uncontaminated product (which can increase sales and customer trust). It also protects your workers from dangerous substances and creates a safe working atmosphere. In addition to that, it can also enhance laminar air flow laminar hood operational efficiency and lower event risks by operating within an ISO 8 Class clean room.

You also need good quality and capable air filters for this class of clean room. Correct air filters are ways of containing the impurities in the atmosphere like fungus, dust mites and other pollutants so that your goods are uncontaminated. This is why the changing of air filters in your clean room should be done regularly and they are working properly. Worker Safety Regulations With Standard ISO 8 Clean Room For Sale By ensuring proper air filtration, companies can achieve these clean room hepa intake filter box classifications and creators a safe working environment.

ISO 8 Class clean room maintenance is a laborious task that involves keeping a close eye and timely perfecting cleaning. One of the best things you can do to keep your ISO 8 clean room up to the high standards it needs is to clean surfaces and air filters regularly while monitoring cleanliness levels. For example, this involves the use of appropriate cleaning procedures and adherence to strict iso level 5 clean room policies to keep a room oh-so-clean. These are some tips, so companies can achieve ISO 8 standard clean room and work in a 100% safe and clean environment.