WHAT ARE ISO 7 CLEANROOM COMMON MISTAKES

This can result in environmental pollution and the degradation of product quality. Another error is that of not donning the appropriate personal protective equipment (PPE) when working within the cleanroom this can introduce contamination and compromised the integrity of a controlled environment. Furthermore, neglecting to continuously monitor and control the air quality, temperature and humidity levels within a cleanroom can lead to non-compliance of prescribed standards and thus also influence the cleanliness in general.

How to Prevent Mistakes and Error for ISO 7 Cleanroom Procedures:

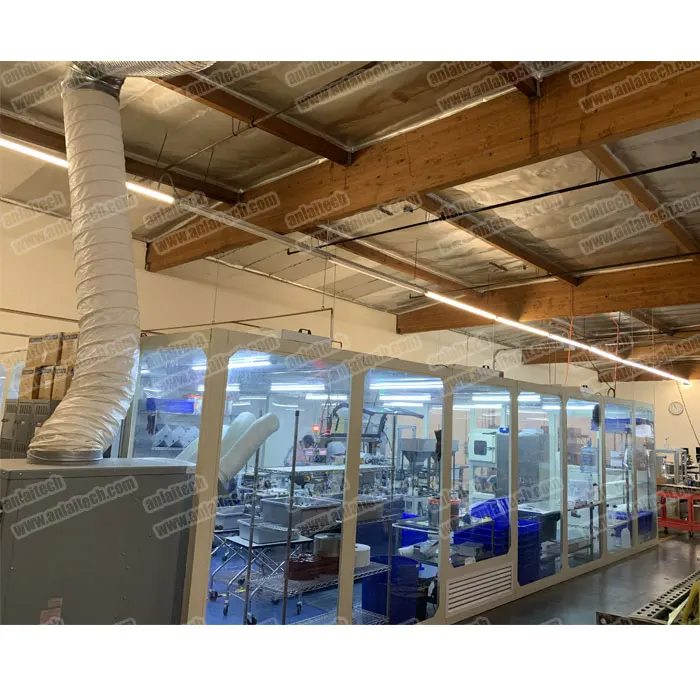

In order to prevent mistakes in cleanroom protocol per ISO 7 standards, it is critical to maintain a stringent formal regimen on class 1000 cleanroom and disinfection. Such should include cleaning of surfaces, equipment and utensils in an appropriate manner. By following the guidelines for gowning and ensuring other PPE equipment masks/hoods and overalls is correctly worn by all staff members, contamination can be restricted from entering cleanroom facilities. The cleanroom standards must be monitored and controlled by using a correct ventilation system, sensors and control units for air quality, temperature as well as humidity. Quality professionals should also train and educate staff regularly, about proper cleanroom protocols and procedures in order to prevent errors as well as so the entire team understands their role in maintaining the controlled environment.

When operating in an ISO 7 cleanroom, there are some mistakes you’ll want to know about because they can affect the cleanliness and productivity of your environment. By knowing what these pitfalls are and how to avoid them, you can rest assured that your operations in a cleanroom environment will run smoothly and successfully., let’s take a look at some wholesale tips for when it comes to maintaining or even improving adherence to ISO 7 cleanroom standards, where you can find quality resources for ensuring best practices for ISO 7 cleanrooms as well as what do you do if you’re confronted with challenges in keeping up with the demands of an ISO 7 operation.

Tips for how to Keep ISO 7 Cleanroom Standards wholesale:

Appropriate gowning process: All the workers who enter a clean room should be well-versed with acceptance, procedure & expectations to prevent cross contamination. This may involve wearing protective clothing, having specially dedicated shoes for use in the iso 5 class 100 cleanroom and adhering to detailed washing rules.

Routine cleaning and disinfection: Essentially, cleanroom surfaces need to be cleaned regularly, if not daily, to avoid accumulation of soil load. All machines sets up in Theaters are to be wiped down with Theater wipes per cleaner and cleaned properly.

Materials and equipment control: All materials and equipment that enter into the cleanroom need to be clean, controlled and sanitized in order to prevent contamination. Establish stringent procedures for handling and storing materials in a clean condition.

Training and education: Employees will need to be trained in proper cleanroom protocols and standards to ensure ISO 7 is preserved. All the employees should have solid understanding of cleanroom do’s and don’ts to avoid errors and ensure adherence.

Where to find trustworthy material on ISO 7 clean room best practices:

ISO guidelines: The International Organization for Standardization offers regulations and standards on the operation of cleanrooms. See ISO 14644 for more detail and recommendations on ISO 7 cleanrooms.

Publications of Cleanroom Technology: Numerous publications and resources offer insight and guidance on cleanroom technology. Read industry publications online and off to keep abreast of developments in cleanroom technology.

Industry conferences and seminars Conferences and seminars for the industry can be a great way to train with experts, get new information on strategy as well as network with other cleanroom practitioners. Find something on cleanroom tech and best practices to grow your understanding and skills.

How to Address the ISO 7 Cleanroom Operation Issues:

Find the root cause: To troubleshoot any class 10000 cleanrooms you want to get to the bottom of what is causing that problem. Investigate in detail, what went wrong and why, so next time you can tackle the problem.

Take corrective action: When you uncover the root cause of the problem, make necessary abatements so that it will never occur again. This might mean revising processes, offering further training or even updating some equipment or systems.

Monitor & review: After corrective action has been taken, monitor and review the new practices. Periodic audit of the cleanroom operation and performance, verify maintained required standard.

On-going improvement: Cleanroom practices need to be a continuous process of will improve its performance. Solicit feedback from employees and stakeholder applying the information to continuously refine cleanroom protocols and policies accordingly.

ISO 7 cleanroom standards are achieved through close attention to detail, best practices, and ongoing commitment to implementation excellence. Through adhering to wholesale cleanroom maintenance tips, identifying reputable sources of best practices, and understanding how to avoid issues that jeopardize success, your cleanroom operations can be as seamless and productive as possible. Cleanliness is paramount in ISO 7 clean rooms, so continue focusing on cleanliness and controlling contamination while working each day.