As global demand for ultra-clean manufacturing environments surges in pharmaceuticals, semiconductors, and biotech, ANLAITECH launches its AL-FFU Series—a revolutionary line of Fan Filter Units (FFUs) engineered to meet ISO 14644-1 standards while reducing energy costs by up to 40%. Combining cutting-edge filtration, IoT-enabled controls, and modular design, these systems address the $9.8 billion cleanroom equipment market’s shift toward automation and sustainability.

Industry Trends Driving Innovation

1. Post-Pandemic Air Quality Demands: With 68% of pharma firms prioritizing contamination control post-COVID-19, ANLAITECH’s FFUs deliver 99.9995% efficiency at 0.1μm via ULPA filters, surpassing FDA and EU GMP requirements.

2. Energy Efficiency Mandates: The AL-FFU Series’ EC motors cut power consumption by 35% vs. traditional AC models, aligning with the EU’s 2030 Carbon Neutrality Goals.

3. Smart Factory Integration: Built-in Modbus compatibility enables seamless integration with Building Management Systems (BMS), critical for Industry 4.0-ready facilities.

Product Highlights & Technical Superiority

1. Ultra-Low Particulate Control

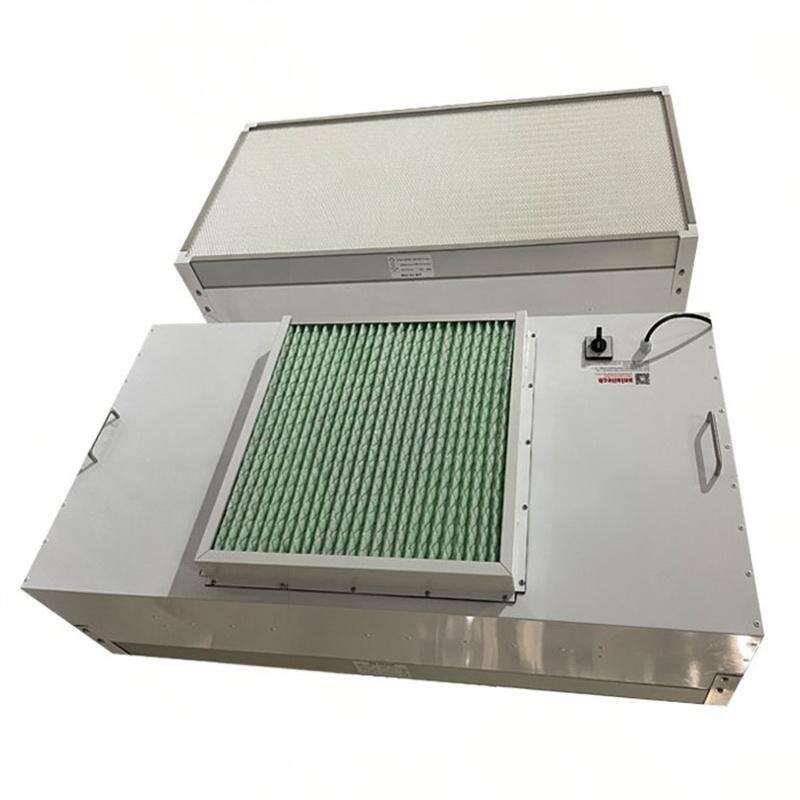

· HEPA/ULPA Flexibility: Choose between HEPA (99.99% @0.3μm) or ULPA (99.9995% @0.1μm) filters, ideal for ISO Class 3–8 cleanrooms.

· Washable Prefilters: Extend filter lifespan by 50% with reusable non-woven fabric prefilters, reducing operational waste.

2. Intelligent Touchscreen Control

· FCU Touch Screen System: Manage up to 300 FFUs from a single interface, with real-time monitoring of air velocity (0.36–0.56 m/s), noise levels (48–62 dB), and fault alerts.

· Adaptive Speed Modes: Optimize airflow with 3–5 adjustable speeds, slashing energy use during low-occupancy periods.

3. Modular & Scalable Design

· Size Variants: From compact 575x575mm units (AL-FFU22) to high-capacity 1175x1175mm models (AL-FFU44), scalable for labs or wafer fabs.

· Material Options: Stainless steel (corrosion-resistant), aluminum (lightweight), or galvanized steel (cost-effective) housings.

Market Applications & Success Stories

· Semiconductor Manufacturing: A Tier-1 chipmaker reduced particle counts by 90% using AL-FFU3*4 units in its ISO Class 5 lithography room.

· Pharma Labs: Modular FFU clusters enabled a Swiss vaccine producer to reconfigure clean zones in 48 hours during peak COVID-19 production.

Sustainability & Compliance

· Global Certifications: CE, RoHS, and REACH compliant.

· Carbon Footprint: EC motor variants reduce CO2 emissions by 12 tons annually per 100 units.

Why choose ANLAITECH?

· Lifetime Support: 5-year warranty with 24/7 global technical assistance.

· Custom Solutions: Super-thin FFUs (≤350mm height) for retrofitting legacy facilities.